Service Engineering

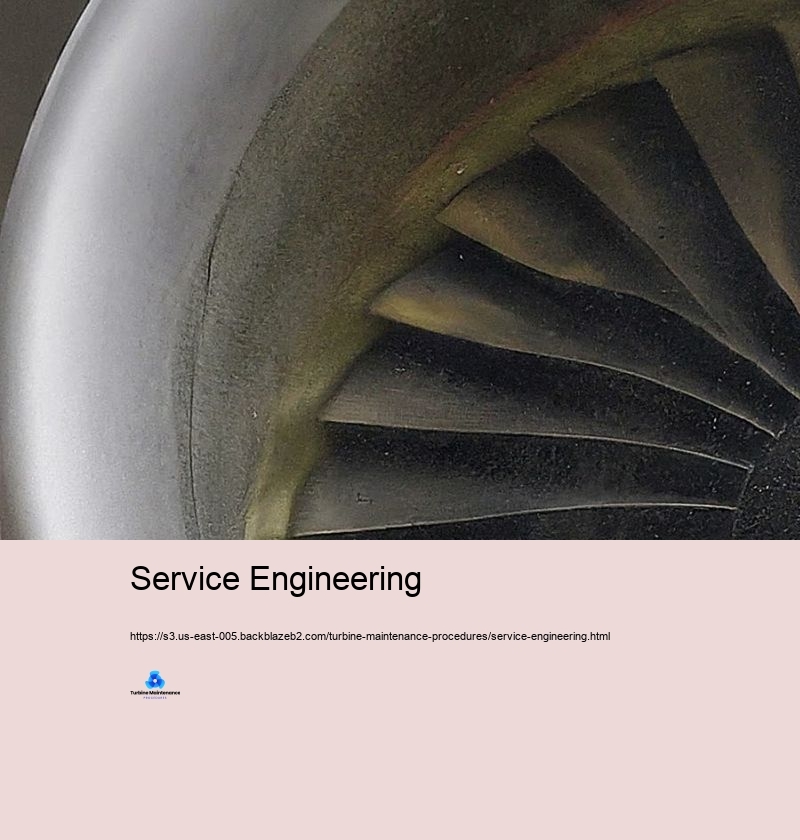

Compressor Blades

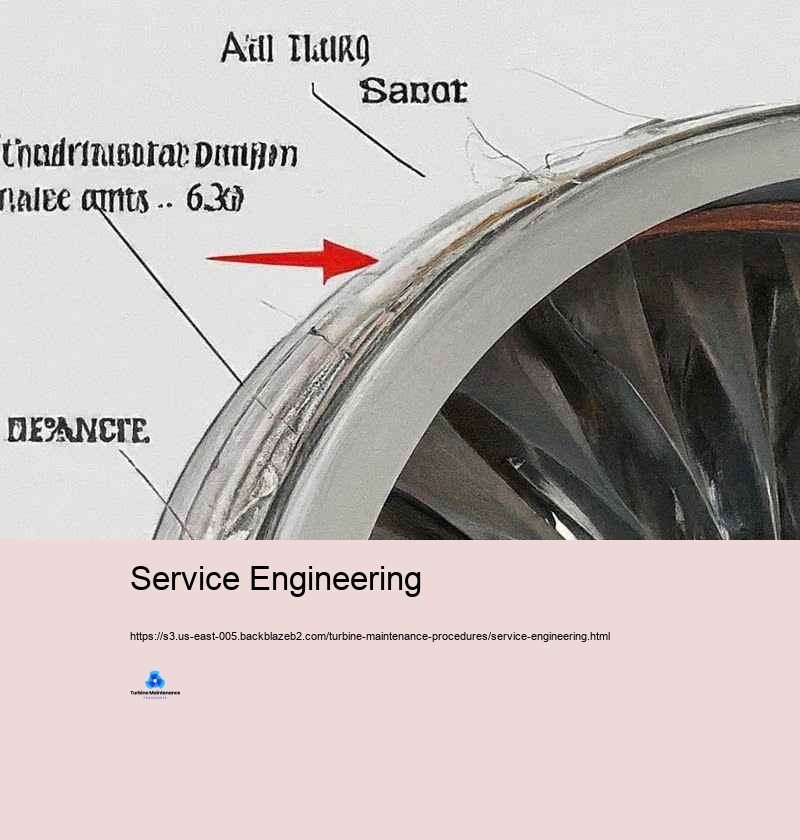

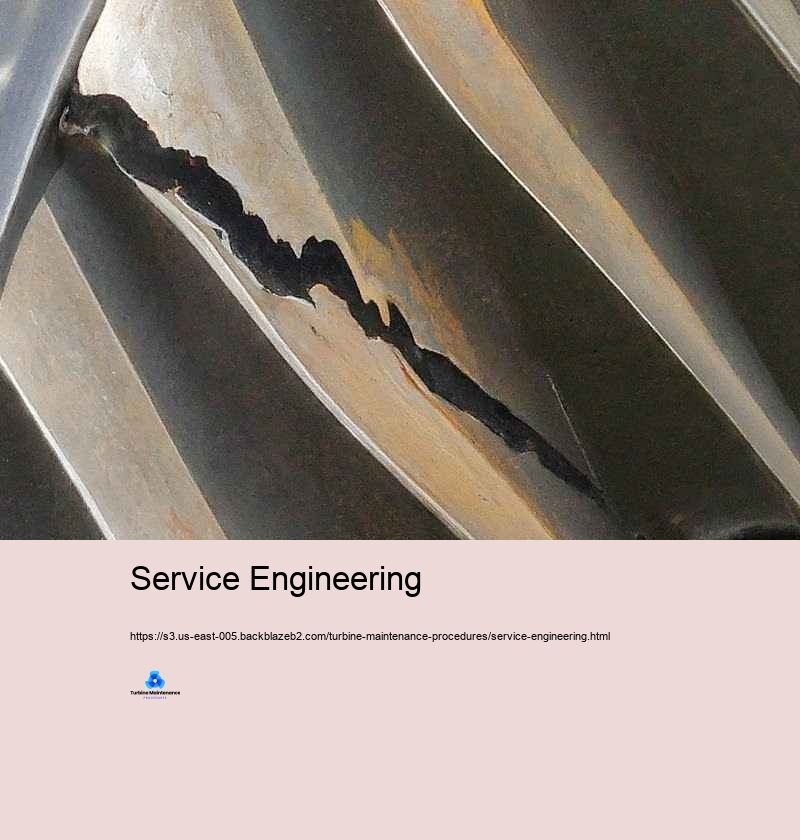

Turbine maintenance is a critical aspect of power generation, commercial procedures, and different various other applications where wind turbines play a vital feature. Correct maintenance ensures ideal performance, expands the life span of the tools, and prevents expensive failings. This introduction to turbine maintenance checks out the important ideas and techniques important for preserving these elaborate makers appropriately. At its core, turbine maintenance is about preserving the sincerity and performance of the turbine system. Generators, whether heavy vapor, gas, or hydraulic, are sophisticated pieces of equipment that change power from a liquid (heavy steam, gas, or water) into power. The high-speed transforming, extreme temperatures, and anxiety involved in their operation make regular and full maintenance important. Among the essential ideas in turbine maintenance is preventative maintenance. This proactive strategy entails regularly established examinations, cleansing, and little repair to stop significant failings prior to they happen. Preventative maintenance generally includes jobs such as lubricating bearings, checking out and changing clearances, checking blades for wear or problems, and watching on resonance levels. By solving tiny concerns early, preventative maintenance can drastically reduce the risk of tragic failures and prolong the turbine's useful life. Condition-based maintenance is one more vital concept that has gotten importance with the advancement of advanced checking advancements. This approach counts on real-time info from sensing units and watching on systems to develop when maintenance is called for. Criteria such as vibration, temperature level, stress, and oil condition are consistently monitored. When these requirements deviate from normal arrays, it programs prospective issues that call for focus. Condition-based maintenance allows much more targeted and trusted maintenance activities, lessening unwanted downtime and making the most of resource allocation. Predictive maintenance takes condition-based maintenance a step far better by using info analytics and expert system solutions to anticipate when failures are more than likely to take place. By assessing historic information and present running problems, anticipating maintenance systems can anticipate potential issues prior to they appear as visible problems. This approach allows maintenance groups to plan interventions at the most desirable times, reducing interruption to procedures and making the most of the effectiveness of maintenance jobs. Alignment is an important technique in turbine maintenance. Proper placing of the turbine shaft with the generator or driven devices is necessary for smooth treatment and long life. Misalignment can bring about extreme resonance, accelerated wear of bearings and seals, and decreased efficiency. Routine positioning checks and adjustments, frequently making use of laser placement tools, are a normal part of turbine maintenance programs. Balancing is an added essential element of turbine maintenance. The high-speed turning of turbine components methods that also tiny inconsistencies can cause considerable vibration and wear. Dynamic harmonizing of blades and impellers is done to make certain smooth procedure. This procedure consists of including or getting rid of percents of weight at certain show achieve optimum balance. Routine resonance analysis helps determine inequality problems early, making it possible for punctual modifications. Compressor Blades Analysis and cleansing of turbine blades are crucial maintenance methods. Blades can experience numerous issues such as disintegration, corrosion, fouling, or physical damages. Regular examinations, often utilizing borescopes or other non-destructive screening methods, aid establish these worries. Cleansing of blades, which could entail chemical cleaning or mechanical methods like grit blasting, aids keep wind resistant efficiency and stops efficiency degradation. Lubrication administration is an important element of turbine maintenance. Appropriate lubrication of bearings, devices, and numerous other moving elements is vital for decreasing rubbing and use. This entails not just ensuring an adequate supply of lubricating substance but additionally checking its top quality. Oil analysis is an usual technique that aids place impurities, placed on bits, and changes in oil domestic or commercial residential properties that can suggest establishing concerns in the turbine system. Seal maintenance is an additional critical approach. Seals safeguard against leakage of working liquids and lubricating substances, and their failing can result in considerable performance losses and feasible safety threats. Regular examination and replacement of seals, particularly in high-pressure or high-temperature areas, is a traditional element of turbine maintenance regimens. Control system maintenance is increasingly essential as generators end up being additional automated and online controlled. This entails normal checks and calibration of sensors, actuators, and control valves. Software program application updates and cybersecurity steps are similarly important facets of modern turbine control system maintenance. Safety and security is essential in all turbine maintenance jobs. Generators include high powers, serious temperature level degrees, and possibly hazardous products. Strict adherence to safety and safety and security procedures, including lockout/tagout procedures, constrained area entry procedures, and appropriate use personal safety devices (PPE), is crucial. Service Engineering Safety training and routine document program for maintenance workers are important methods in turbine maintenance programs. Paperwork and record-keeping are important approaches in turbine maintenance. In-depth logs of all maintenance activities, consisting of assessments, repair work, and component replacements, provide crucial historical information for pattern evaluation and future maintenance planning. Numerous business currently utilize electronic maintenance keeping an eye on systems (CMMS) to improve this procedure and aid with information evaluation. Training and capacity improvement of maintenance workers is a recurring technique in turbine maintenance. As turbine technologies progress, maintenance methods and tools furthermore progression. Regular training programs make sure that maintenance group are existing with the current maintenance strategies, analysis gadgets, and safety and security and security procedures. Ecological factors to consider are ending up being substantially crucial in turbine maintenance. This consists of appropriate taking care of and disposal of hazardous items like utilized oils and tidying up chemicals. Numerous maintenance techniques now focus on reducing eco-friendly impact while making certain optimal turbine performance. Turbine maintenance is a complex and varied field that incorporates mechanical, electric, and gradually, electronic proficiency. The vital principles of preventive, condition-based, and predictive maintenance develop the structure of modern turbine maintenance techniques. Practices such as positioning, balancing, blade examination and cleansing, lubrication monitoring, and control system maintenance are essential for assuring the dependability, efficiency, and resilience of turbine systems. As turbine technologies stay to breakthrough, maintenance techniques will furthermore development, incorporating brand-new technologies and strategies to meet the obstacles of preserving these essential tools in an ever-changing energy landscape.